Wood Pellet Production Process.

1.Wood Chipping and Crushing Stage:

This phase involves a wood chipper or a combination of a wood shaving machine and a wood crusher. Both types of machinery are manufactured by our company. This stage also necessitates a conveyor system for material transport.

Wood Pellet Production Process.

2. Drying Stage:

The drying process requires a rotary drying airflow combination machine, installation of pipelines, a shaker screen, airlock valves, blowers, and belt conveyors for efficient drying of the wood material.

Wood Pellet Production Process.

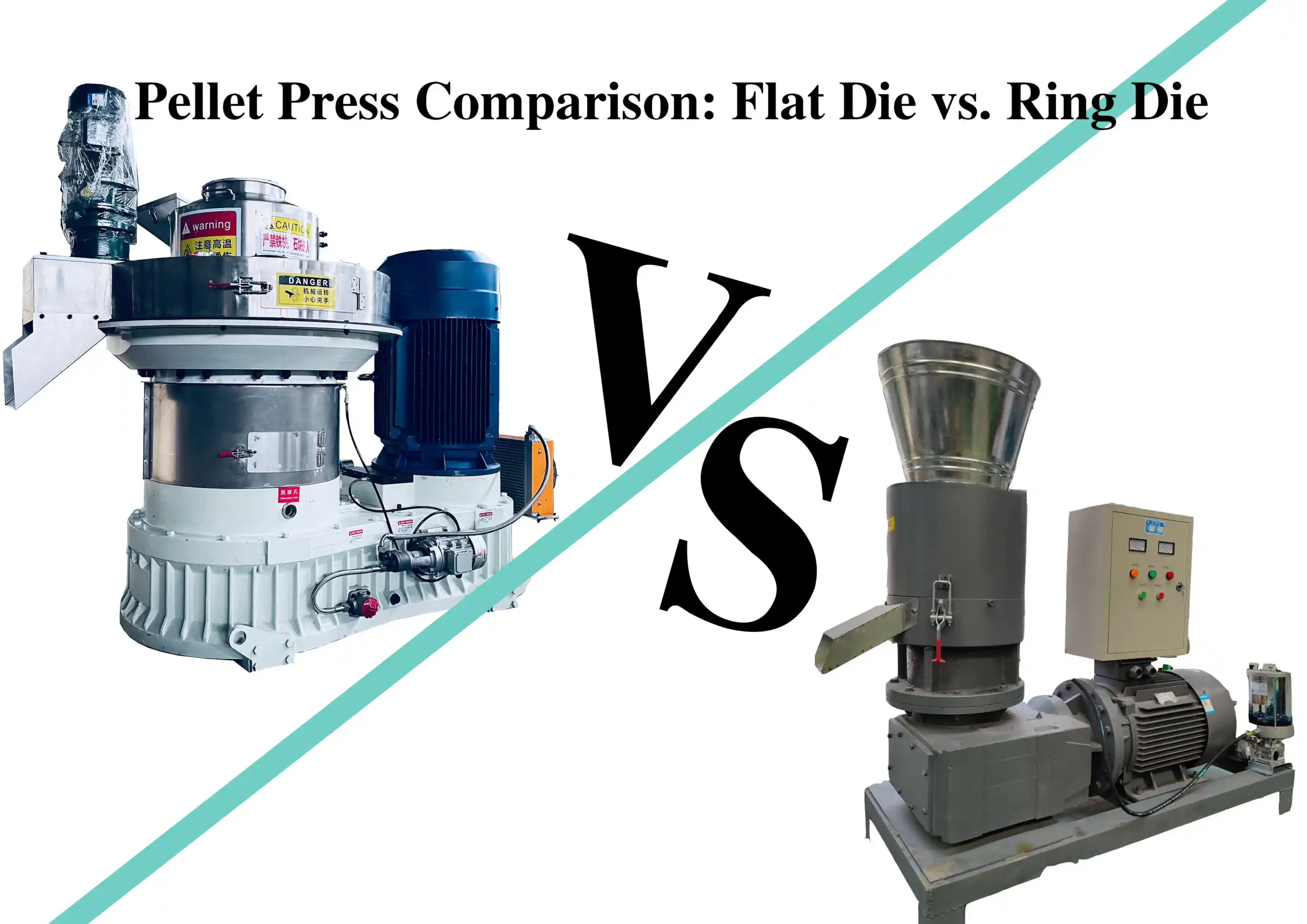

3. Pelletizing Stage:

Pellet production involves several crucial equipment pieces, including elevators, permanent magnetic cylinders, level indicators, U-shaped screw conveyors, pneumatic valves, storage silos for raw materials, pelletizers, belt conveyors, bucket elevators, and additional airlock valves.

Wood Pellet Production Process.

4. Cooling Stage:

For cooling the pellets, this stage incorporates a cooling machine, fans, shaker screens, blowers, complemented by installation pipelines, grading sieves, spiral conveyors, dust removal systems, and air ducts.

Wood Pellet Production Process.

5. Finished Product Packaging Stage:

Packaging the final product requires elevators, storage bins for the finished product, level indicators, and computerized packaging scales.

Wood pellet production is a harmonious orchestration of these interconnected stages. Each phase plays a pivotal role, and only when each component operates seamlessly can high-quality wood pellets be manufactured.

Wood Pellet Production Process.

6.Elaborating on Wood Pellet Manufacturing Efficiency:

Efficiency in wood pellet production is vital for productivity and cost-effectiveness. A streamlined process ensures optimized use of resources and minimizes waste. Our integrated production lines are designed to maximize efficiency at each stage, allowing for a significant increase in output.

The synergy between the chipping, drying, pelletizing, cooling, and packaging stages enables a smooth transition of raw wood material to finished pellets. By employing advanced machinery and a systematic approach, our production lines have been tailored to meet the demands of high-capacity wood pellet manufacturing.

Wood Pellet Production Process.

Conclusion:

The production of wood pellets involves a sophisticated process that demands precision and synchronization among diverse equipment and stages. Our comprehensive understanding of this process allows us to provide reliable and efficient wood pellet production solutions, meeting both industry standards and environmental considerations.

For small businesses we have produced a convenient small wood pellet machine. Click to see more details